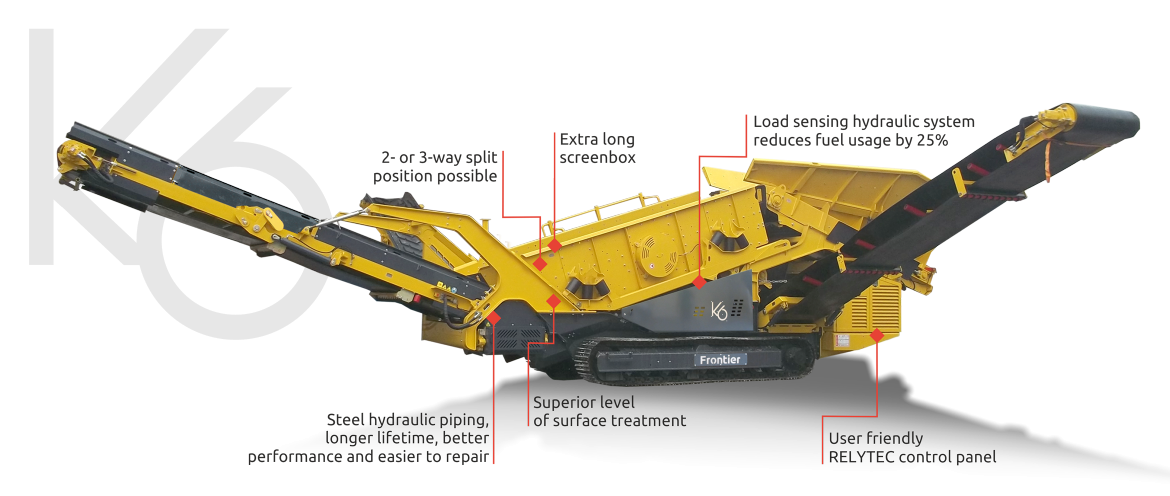

K6

Product information

Download brochure (PDF)

Download Broschüre (PDF)

Scarica il dépliant (PDF)

Загрузить брошюру (PDF)

Brochure downloaden (PDF)

Télécharger la brochure (PDF)

Descargar folleto (PDF)

Stáhněte si brožuru (PDF)

Завантажити брошуру (PDF)

Performance highlights

- Introduced by Keestrack in 1996 and due to R&D most mature unit on the market

- Unrivalled Performance

- Available in full hybrid version

- Standard heavy duty plate apron feeder and hydraulic folding hopper walls

- Double deck screen box 4.500 x 1.800 mm (15’ x 6’)

- 8,1 m² screening surface on each deck

- Liftable screenbox to get easy access to change screens

- Capacity up to 600 tonnes / hour

- Feed hopper 8 m³ (10 yard³), several hopper extensions available

- Low emission engine

- Lowest fuel consumption in the industry

- Large range of screen meshes, fingers, punched plate, grizzly & rubber decks available

- 2 speed track drive

- Extensive option list to configure to your application

Specifications

| Transport dimensions | Working dimensions | |

|---|---|---|

| Weight | 30 t (33 sT) | |

| Length | 13.360 mm (43’10”) | 15.400 mm (50’6”) |

| Height | 3.180 mm (10’7”) | 3.700 mm (12’2”) |

| Width | 2.720 mm (8’10”) | 14.400 mm (47’3”) |

| Transport dimensions | Working dimensions | |

|---|---|---|

| Weight | 30 t (33 sT) | |

| Length | 13.360 mm (43’10”) | 15.400 mm (50’6”) |

| Height | 3.180 mm (10’7”) | 3.700 mm (12’2”) |

| Width | 2.720 mm (8’10”) | 14.400 mm (47’3”) |

Fuel efficiency

Applications

- Pre- screening/scalping

- Screening heavy over-burden

- Recycling landfill and construction waste

- Top soil and many other products

- Separation of “sticky” aggregate

- Construction and demolition waste

- Screening behind or before a crusher

- Sand and gravel

- Quarrying and mining

- Coal

- Wood and others