Cribas

Variedad de cribas

Aspectos generales

Keestrack fue la primera empresa en construir cribas de alimentación directa. Incluso a día de hoy, la competencia es incapaz de alcanzar los resultados que conseguimos con este concepto. El concepto original de Keestrack es actualmente la norma para el sector. Gracias a este concepto, el campo de aplicación de nuestras cribas se ha ampliado puesto que la criba puede usarse como precriba para material grueso o como criba de precisión para materias finas.

Nuestras separadoras, clasificadoras y cribas de tambor ofrecen alto rendimiento y soluciones de gran transportabilidad, independientemente de la tarea que realicen.

Beneficios clave

- Rendimiento incomparable

- Versiones eléctricas conectables disponibles para ahorro de energía

- El menor consumo de combustible de la industria

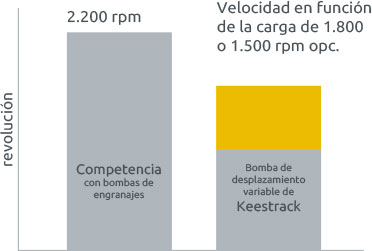

Velocidad de motor necesaria para lograr máxima productividad

Separadora Serie K

Separadora Serie K

Clasificadora Serie C

Clasificadora Serie C