Zeven

Aanbod zeven

Overzicht

Keestrack was de eerste om een zeefmachine met directe toevoer te ontwikkelen en zelfs vandaag kan de concurrentie de resultaten die we met dit concept realiseren niet evenaren. Het originele Keestrack-concept is vandaag de industrienorm. Dankzij dit concept zijn de toepassingsdomeinen toegenomen omdat de zeef niet alleen als voorzeef voor grof materiaal maar ook als fijnzeef voor fijne fracties kan worden gebruikt.

Onze grof- en fijnzeven bieden oplossingen met uitstekende prestaties en een hoge mobiliteit, wat er ook moet worden gedaan.

Belangrijkste voordelen

- Ongeëvenaarde prestaties

- Elektrische, energiezuinige stekkeruitvoeringen verkrijgbaar

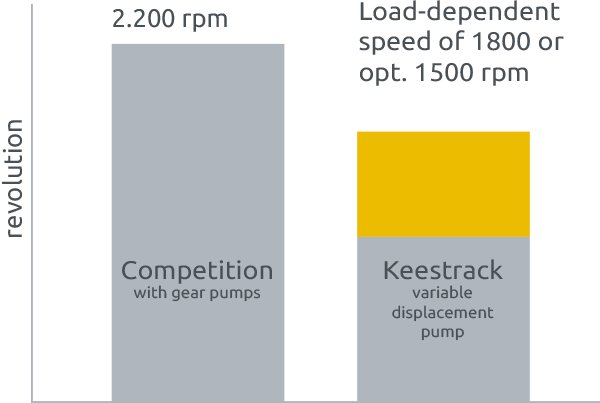

- Laagste brandstofverbruik in de industrie

Vereist motortoerental voor maximale productiviteit

Grofzeef K Serie

Grofzeef K Serie

Fijnzeef C Serie

Fijnzeef C Serie