Грохоты

Линейка грохотов

Обзор

Компания Keestrack первой выпустила грохоты с прямой подачей, и даже сегодня конкуренты не могут достичь результатов, которые мы имеем с применением этой концепции. Оригинальная запатентованная концепция Keestrack — стандарт в отрасли. Благодаря этой концепции области применения наших грохотов расширились, поскольку грохот можно использовать для предварительного отсева необработанного материала или для тщательного отсева мелкой фракции.

Первичные и вторичные грохоты Keestrack предлагают высокопроизводительные решения с высокой мобильностью-независимо от задачи.

Основные преимущества

- Непревзойдённая производительность

- Электрический, энергосберегающий, с подключением к сети версия доступна

- Самое низкое потребление топлива в индустрии

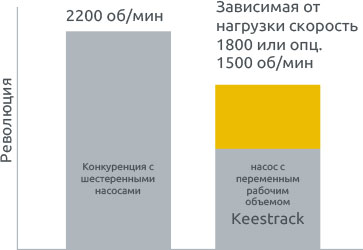

Частота вращения двигателя,необходимая для достижения максимальной производительности

Первичные грохоты К серии

Первичные грохоты К серии

Вторичные грохоты С серии

Вторичные грохоты С серии