Дробилки

Дробильное оборудование

Обзор

Наш ассортимент щековых, конусных и роторных дробилок обеспечивает непревзойдённую производительность и мобильность в широком диапозоне примений.

Основные преимущества

- Превосходная форма

- Максимальный коффициент сокращения

- Возможность отслеживания во время произвоства

- Приемный бункер походящий для колесного погрузчика и экскаватора

- Удобные и компактные размеры для транспортировки

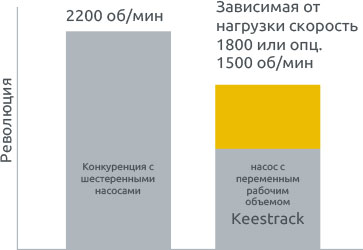

Частота вращения двигателя,необходимая для достижения максимальной производительности

Щековые В Серии

Щековые В Серии

Роторные Серии R

Роторные Серии R

Конусные Н Серии

Конусные Н Серии