Drtiče

Drtiče

Přehled

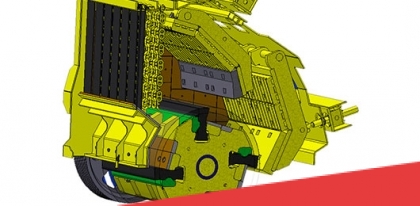

Náš sortiment čelistních, kuželových a odrazových drtičů poskytuje bezkonkurenční výkon a mobilitu v širokém spektru aplikací.

Klíčové výhody

- Vynikající tvarový index

- Nejvyšší redukční drtící poměr

- Možnost drtit/třídit i při pojíždění

- Násypka vhodná pro kolový nakladač a rypadlo

- Snadná přeprava a kompaktní rozměry

Otáčky motoru nastavené k dosažení maximálního výkonu

B-Čelisťové

B-Čelisťové

R-Odrazové

R-Odrazové

H-Kuželové

H-Kuželové