Fuel efficiency

Reduce fuel costs and CO2 emissions

We know our customers need exceptional power and performance, but they also want to lower their fuel costs and reduce their environmental footprint.

Striving to meet these demands Keestrack are at the forefront of deploying fuel saving technologies such as load-sensing hydraulics and hybrid diesel / electric drive options – two great ways to reduce fuel consumption with no loss of performance.

We offer modern low-emission diesel drives with load-sensing hydraulic modules for power units and crusher functions on all our products. These offer potential fuel savings of approximately 25% over conventional drives. And our electric options provide even greater scope for savings of energy and CO2 emissions.

Load-sensing Hydraulic System

Keestrack have been pioneering the use of load-sensing hydraulic systems for many years. The hydraulics monitor feed load and automatically adjust to the requirements of the load. As a result, 4-6 liters of fuel can be saved per hour, and when applied to typical operation of 1,500 hours, this equates to a saving of up to 7,500 litres.

The load-sensing systems provide cost savings of approx. 30% compared to crushers and screeners, offered by other manufacturers, who do not apply this technology.

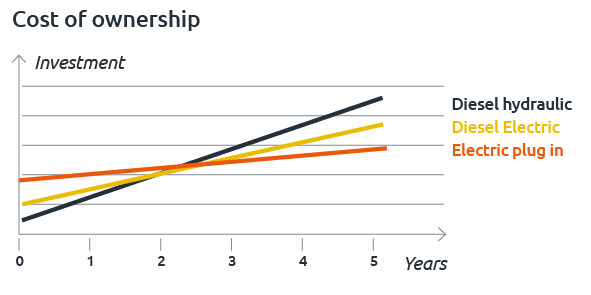

Hybrid diesel / electric drive options

Keestrack introduced the first hybrid classifier C6 in 2012 and has been continuing this path ever since as we believe this is not just an added value for the environment but it is also a significant improvement on the cost efficiency of our machines.

Keestrack delivers several optional drive systems with plug in and plug out options. The performance and end results are identical to the standard diesel/hydraulic driven machines but energy costs, maintenance costs and cost of ownership are significantly lower. And our electric options provide even greater scope for savings of energy and CO2 emissions.

Fuel & energy consumption for C6 Classifier

Diesel/hydraulic

Diesel/hydraulic model with standard load-sensing hydraulic system consumes approximately 14 litres an hour.

Electric drive via onboard Genset

Electric drive via onboard Genset powered by a C6 diesel engine consumes approximately 9 liters an hour.

This results in fuel savings of approximately 33% when compared to a C6 with diesel/hydraulic drive.

And when compared with other classifierson the market (who do not use load sensing hydraulic systems) fuel savings can even rise to over 50%.

Plugged into crusher

Connected to a crusher results in a fuel consumption of 4 litres more of the crusher total consumption.

Electric drive via electrical mains

Connected directly to the mains supply energy savings can be approximately 60% when compared to a diesel/hydraulic model.

And when compared with other classifiers on the market (who do not use load sensing hydraulic systems) fuel savings can even rise to nearly 70%.